Matthew KenyonExpertise Reporter, Delft, Netherlands

The ultimate take a look at was a blunt one. Maarten Logtenberg wielded a sledgehammer, which merely bounced off the pattern, barely leaving a scratch.

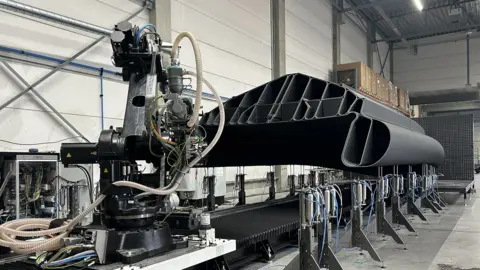

After two years of experimentation, the fabric was lastly proper: a specific mixture of thermoplastics and fibreglass that’s sturdy, has no want of additional coating to guard it from daylight, and is immune to fouling and marine progress.

The proper base, says Mr Logtenberg, from which to 3D print a ship.

Boats want to face up to the unforgiving nature of the marine atmosphere. It is one of many explanation why boatbuilding is a notoriously labour-intensive enterprise.

However after months of tweaking the chemistry, it took simply 4 days for the primary hull to roll off the printer on the new manufacturing facility that Mr Logtenberg and his colleagues run.

“We’re automating virtually 90% of the boat-building course of, and in superfast time,” he says.

“Usually it takes weeks to construct a hull. We print one now each week.”

It is the type of story that 3D printing has lengthy promised. A fast, labour-saving manufacturing course of that drastically reduces prices.

These guarantees have not all the time been fulfilled – however Mr Logtenberg is satisfied that the maritime sector is one the place 3D printing, often known as additive manufacturing, can play a transformational position.

Mr Logtenberg is the co-founder of CEAD, an organization that designs and builds large-format 3D printers at its base within the Dutch city of Delft.

Till now, its enterprise has been to offer the printers for others to make use of, however with boatbuilding CEAD determined to become involved in manufacturing as nicely.

“3D printed boats nonetheless have to be accepted by the market,” says Mr Logtenberg.

“Individuals are not going to speculate after which simply hope that the market will develop. They’d reasonably purchase in capability first. [So] as an alternative of simply constructing machines, we will do it ourselves.”

CEAD

CEADConventional fibreglass boat constructing requires a mould and appreciable handbook work to ensure the vessel is of the required power.

In additive manufacturing, the work has already been completed on the design stage, in creating the software program and the printer itself (which is labour intensive).

3D printers work by build up tiny layers of the essential materials, to a predetermined digital design.

Every layer then bonds to the earlier one to permit the creation of a single, seamless object.

Within the manufacturing part, so long as there’s a provide of the bottom materials, there may be little or no want for human intervention.

The design may also be adjusted with out the necessity for main modifications within the construct course of.

A lot 3D printing operates on a comparatively small scale – dentistry is one space the place it has made a serious influence. To create a ship able to working in actual world circumstances is a unique problem.

CEAD’s largest 3D printer is sort of 40m (131ft) lengthy, and has been utilized by a buyer in Abu Dhabi to print an electrical ferry.

And within the 12 months since they’ve been working the Marine Utility Centre in Delft, they’ve already constructed a prototype 12m quick boat, just like a RIB, for the Dutch Navy.

“Usually when the Navy buys a ship, it takes them years earlier than they obtain it they usually pay fairly some cash,” says Mr Logtenberg.

“We did it in six weeks and for a really restricted price range. And we will be taught from it and construct one other one in six weeks and even recycle the primary one.”

One other quick progress space is using unmanned vessels – nautical drones. CEAD just lately took half in a take a look at with Nato Particular Forces during which drones had been constructed on website in a matter of hours, with designs altering based on operational necessities.

The power to relocate manufacturing makes 3D printing extremely versatile, based on Mr Logtenberg.

Even a considerable printer could be carried in a delivery container and brought a lot nearer to the tip person.

“It does not matter whether or not it is a 6m small work boat or a 12m navy boat. The machine simply takes all of it so long as we now have the design.

“The one transport we have to do is the bottom materials, which is available in large luggage and it’s extremely transport environment friendly, in comparison with a ship.”

Matthew Kenyon

Matthew Kenyon Uncooked Concept

Uncooked ConceptNot removed from CEAD, within the port metropolis of Rotterdam, an organization known as Uncooked Concept and their ‘Tanaruz’ model are making an analogous influence within the leisure market, particularly leases.

“Customers are hesitant [because of the novelty], however the rental market is basically eager,” says Joyce Pont, Uncooked Concept’s managing director.

“It is advertising and marketing, you possibly can go to the socials and say, ‘we have got a 3D printed boat’, and everyone desires to have a look at and contact that boat.”

One other promoting level is that Uncooked Concept makes use of a mixture of glass fibre and recycled client plastics (fizzy drinks bottles and so forth).

That is one motive why the value is at present similar to a traditionally-built boat, as a result of recycled materials prices extra to purchase.

However Ms Pont says scale and suppleness will carry prices down considerably.

“I am satisfied that in 5 years from now, 3D printed boats will take over the marketplace for the fast-driving boat, like work boats, like pace boats,” she tells me.

The marine trade is very regulated however the certification authorities are having to maintain tempo with innovation.

Each RAW Concept and CEAD are partaking with European regulators virtually in actual time, as they use new supplies and new concepts to provide vessels that can’t be in comparison with what has come earlier than.

3D printing has typically been hailed as a revolutionary know-how however hasn’t all the time delivered on these hopes.

Mr Logtenberg says that is as a result of the approach is utilized in a number of totally different contexts.

“It is all being seen as one factor, however you’ve gotten steel printing, you’ve gotten polymer or large-scale printing, all these totally different purposes.

“There are a lot of purposes that did not succeed as a result of it was not aggressive sufficient, however there are a number of the place it truly occurred and is getting used.”

Additive manufacturing is getting used extra ceaselessly within the delivery trade, however in technical niches, reasonably than complete hulls.

How far may 3D printing go within the maritime world? We’re a good distance from complete ships being printed in a single go.

Joyce Pont is sceptical whether or not that second will arrive within the foreseeable future – she sees the constructing of superyachts and different such vessels as a ‘craft’ which is able to resist automation.

However Mr Logtenberg is extra optimistic.

“Constructing a 12-meter boat, I by no means anticipated {that a} yr in the past,” he says.

“Conventional shipbuilding is finished in modules. It will take possibly a decade or two earlier than we’re going to utterly print [a ship’s hull], as a result of there shall be extra want of fabric analysis.

“However thermal plastics are being developed and improved on a regular basis. After all, the machines, every part must be scaled up, however why not?”